Hyundai’s plant in Nošovice finds itself in a challenging situation this year: while the automaker aimed to increase the share of fully electric vehicles to 17% of total production, demand has fallen short, reaching only 10%. This marks a drop of three percentage points from last year and poses a significant issue for production planning and contractual obligations with suppliers. At a conference focused on the future of the automotive industry, company spokesperson Petr Michník confirmed this trend, emphasizing that fluctuations in demand for electric vehicles complicate Hyundai’s long-term production strategy.

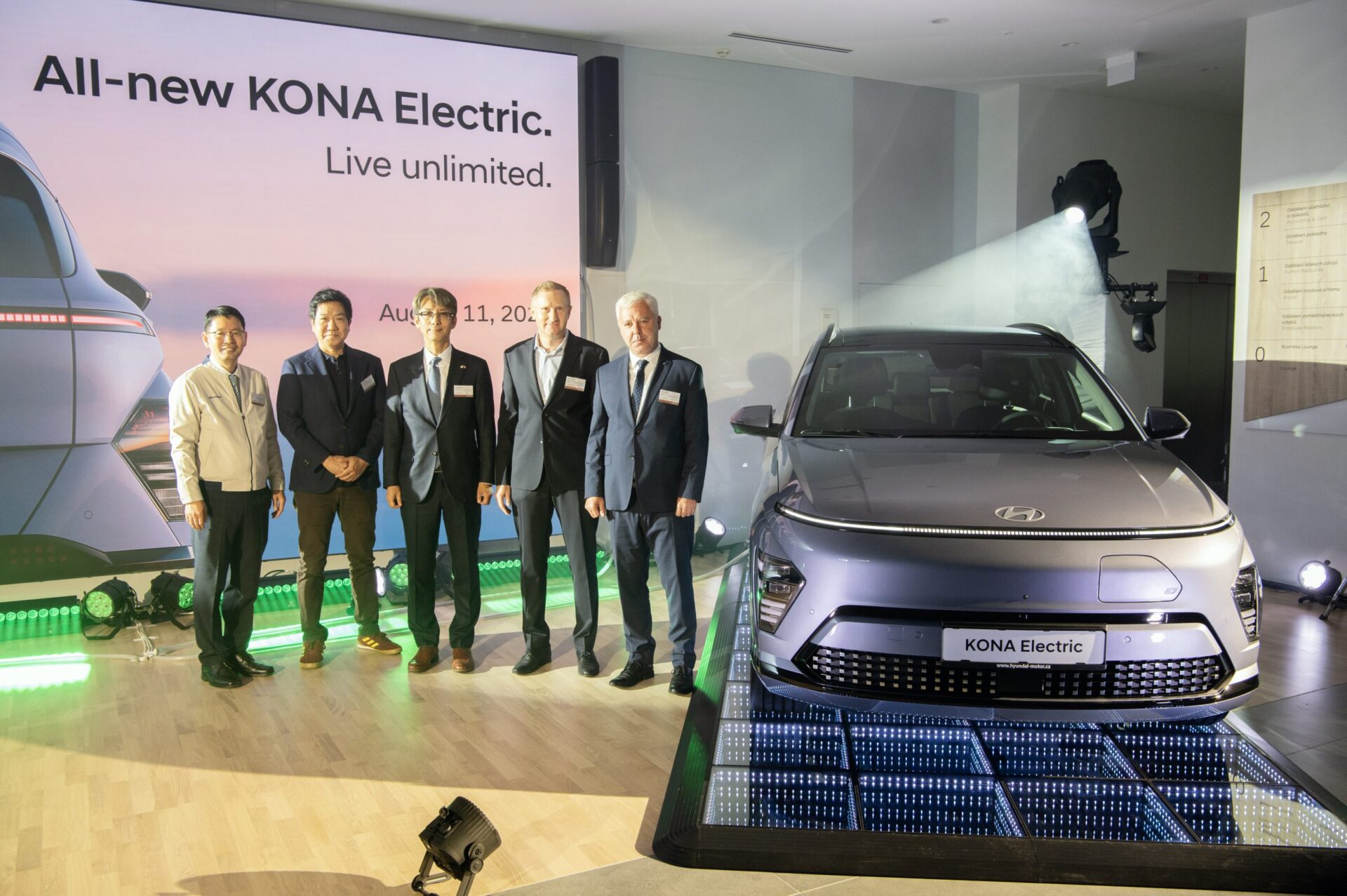

The Nošovice plant currently manufactures only one electric model, the Hyundai Kona, which has been directly impacted by this lower demand. According to Michník, the gap between planned and actual sales is evident: “Ten percent is not insignificant, but the difference from expectations is a problem. We have contracted capacities with battery manufacturers, but demand doesn’t match up with those agreements. On the other hand, hybrid component suppliers are struggling to meet high demand,” he noted. Hyundai’s focus on electric mobility as the future of automotive technology thus faces the challenge of finding an optimal pace of transition that aligns with real market demand.

This uncertainty is further exacerbated by evolving emissions regulations. Starting next year, the European Union will implement stricter standards aimed at reducing transport emissions and encouraging automakers to produce low-emission vehicles. Michník pointed out that if Hyundai in Nošovice fails to manufacture and sell a sufficient number of low-emission cars, it risks incurring fines. However, solutions are not straightforward: “An economically viable solution is complex. Many alternatives don’t make sense for us, for customers, or perhaps even for Europe as a whole,” he added. This perspective highlights the pressure on Hyundai to balance technological ambition with real demand.

Hyundai also has broader plans reflecting a strategy of gradual growth in electric mobility. Including hybrid models, vehicles with alternative powertrains currently make up 40% of the total production at the Nošovice plant, thanks to demand not only from Europe but also from other markets. For Europe, the share of these vehicles is even higher, as the region is more receptive to electric mobility. Hyundai continues to bet on the dominance of electric vehicles and plans to increase their share in total production to 30%, with further preparation for a potential rise to 50%. Additionally, the plant will expand battery production capacity next year by repurposing one of its production halls.

This year, Hyundai’s Nošovice plant is estimated to produce over 330,000 vehicles, employing 3,100 staff members. Hyundai Motor Group, headquartered in South Korea, has even more ambitious plans: by 2030, it aims to increase global production to 5.5 million vehicles annually, representing a 30% increase from last year. Of these, two million are expected to be electric vehicles, with the range of electric models expanding to twenty-one. The number of hybrid models is also expected to double—from seven to fourteen.

The expectation that the electric vehicle market would grow rapidly has not yet been fully realized. The question remains whether Hyundai in Nošovice will be able to meet these challenges and adapt its production to satisfy market demands while avoiding the economic impacts associated with lower demand. Given Hyundai’s plans, it will be interesting to see how the company addresses these ambitious goals and whether it can establish itself as a significant player in electric mobility.

Source: auto

Leave a Reply