Brakes are one of the key elements of any car, yet their basic principle hasn’t changed in nearly 70 years. Now, a groundbreaking technological shift is on the horizon, courtesy of Mercedes-Benz. The automaker is developing a system called In-Drive, which could change the rules. This system moves the brakes from their standard position at the wheels directly to the vehicle’s center, integrating them into the electric motor.

Why change what already works?

The history of brakes has evolved significantly—from drum brakes to disc brakes and today’s sporty carbon-ceramic options. However, the core mechanism has remained unchanged since the 1950s, when disc brakes first appeared at the Le Mans races.

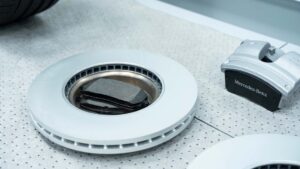

Electromobility, however, is taking braking into a new dimension. Electric cars already rely heavily on regenerative braking, which slows the vehicle while preserving the traditional brakes. As a result, disc brakes are often underused, leading to corrosion or unexpected maintenance costs—see the issues with the Tesla Model 3. Mercedes is therefore seeking a way to make brakes more efficient, durable, and environmentally friendly, as brake dust contains harmful particles.

Electromobility, however, is taking braking into a new dimension. Electric cars already rely heavily on regenerative braking, which slows the vehicle while preserving the traditional brakes. As a result, disc brakes are often underused, leading to corrosion or unexpected maintenance costs—see the issues with the Tesla Model 3. Mercedes is therefore seeking a way to make brakes more efficient, durable, and environmentally friendly, as brake dust contains harmful particles.

How do In-Drive brakes work?

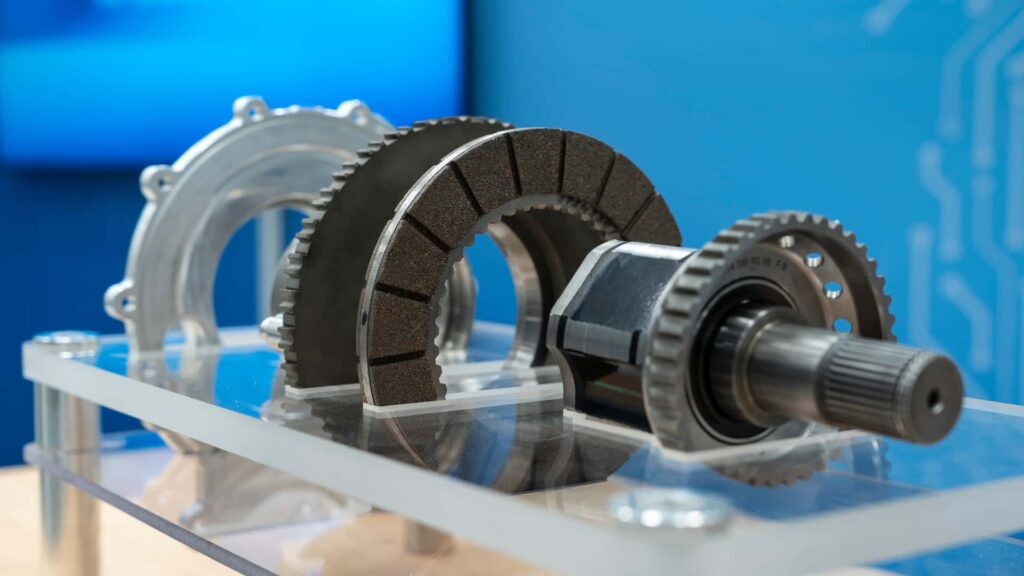

The brakes are relocated from the wheels into a closed system within the electric motor, operating in reverse—rather than spinning discs, the brake pads move. This design allows the entire surface of the disc to be engaged, improving braking efficiency while requiring less pressure.

Another critical advantage is the reduction of unsprung weight. Wheel-mounted brakes are heavy and strain the suspension, impacting vehicle handling. Moving them to the car’s center improves driving dynamics and reduces the material demands for wheels and suspension. Lower unsprung weight also positively affects fuel efficiency.

The benefits of this new solution

Mercedes expects In-Drive brakes to be virtually maintenance-free. Their closed design eliminates corrosion and brake dust, contributing to cleaner operation and lower emissions. Additionally, the new system could allow manufacturers to fully enclose the wheels (as cooling won’t be needed), improving aerodynamics and extending the range of electric vehicles.

The brakes are designed to last up to 15 years or 300,000 kilometers, far outpacing current technologies. Mercedes is also working on integrating the system with ABS and other safety features to ensure maximum reliability.

Start installing them already!

Despite all the advantages, the project is still in development. Engineers are tackling challenges like optimizing the cooling fluid and ensuring compatibility with other vehicle systems. Mercedes has yet to announce a specific release date for this technology in production vehicles.

Leave a Reply